Direct observations are a method for identifying impediments to construction productivity, by viewing and taking notes on the actual activities of the workers in the field. It’s a process of focusing on the processes that workers work with and work with the workers to reduce these impediments.

Employees & Managers who are involved in process improvement initiatives in their area of work.

Provide candidates with an overview of Direct Observations & what the process involves.

Principles of Direct Observation.

The Direct Observation Process.

Prior, during & post direct observations & improving from findings.

LTSL will work with team and decide on a selected area (to be completed over a two day period)

LTSL will carry out Direct Observations on site.

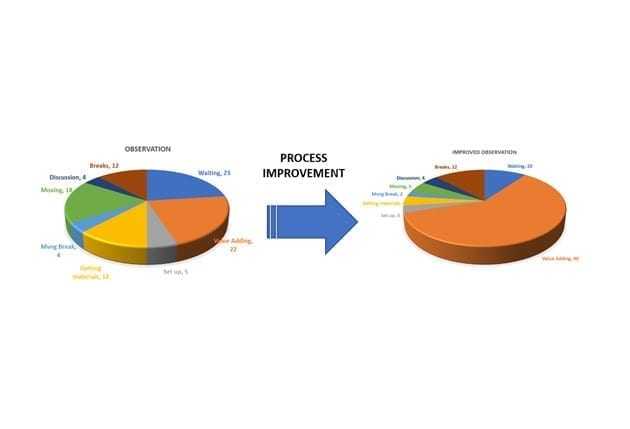

Team focus on the largest wastes observed and plan & execute to reduce.

Once wastes reduced Direct observation is carried out to verify improvement in area.

Programme Details:

Training & direct observations provided by Lean Touch Solutions.

coming soon